Electronic repair

& renovation company

Startup

About the system

A system for monitoring and blocking freon leaks in low-temperature chamber complexes in supermarkets in 24/7 mode on the website of a supermarket company with gas analyzers for monitoring the quality of freezing and cooling of products.

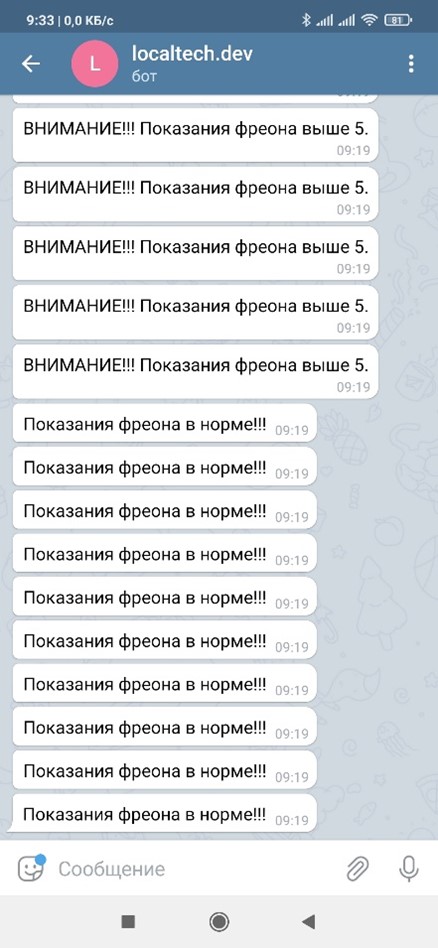

A data monitoring program with a circular cycle of up to 24 nodes per gas analyzer (with a spare gas analyzer installed in the data monitoring system) with a number of such complexes up to 100 units in 24/7 mode on the company’s website with simultaneous duplication of data to a telegram channel with alarm calls to interested parties and, when a certain level of node data is exceeded, a signal is given to block it.

System for monitoring and blocking freon leaks in low-temperature chamber complexes in supermarkets in 24/7 mode on the website of a supermarket company with up to 100 stores with a mobile application. Each chamber has a well-frozen product and gas analyzers to control the quality of freezing and cooling of products.

We produce

Until now, there is no method and devices for automatic monitoring and blocking of freon leaks of low-temperature volumes of complexes in supermarkets up to 100 units on the company’s website in 24/7 mode and a system of gas analyzers for digital monitoring of the quality of frozen and chilled products in 24/7 mode. Only in the European Union there are up to 10,000 such complexes up to 24 chambers in one complex. Helps to avoid fines for emissions of fluorocarbons, is directly aimed at the Decarbonization program of the European Union, China, eliminates the possibility of freon leaks, reduces the cost of maintenance by refrigeration service companies.

The system operates automatically 24/7, under each chamber there is a polymer tube that periodically sucks in air and determines the freon content. The freon monitoring system consists of a suction system of micropumps that periodically suck in air under each of the chambers. Since freon is heavier than air, it seems to fall to the floor and is in no hurry to spread. If the freon content exceeds 10 ppm for 3 cycles, the system blocks the flow of freon into the chamber. The air suction cycle under the chambers of a complex of 16 chambers is about 5-6 minutes. The problem for the management of the supermarket and servicing refrigeration enterprises is the untimely (several days) arrival of refrigeration workers. During this time, if the complex of chambers has a centralized filling with freon, all chambers lose freon. In addition to environmental damage, the supermarket suffers losses from defrosting products and losing their quality, work on transferring to other chambers, if any. Freon losses are 200-300 kg at a price of up to 50 euros, up to 15,000 euros.

This work was carried out for Metro Ukraine

A pressing task for service refrigeration enterprises and supermarket chains, where there are complexes of refrigeration chambers with frozen products: fish, ice cream, frozen vegetables and other products.

Our competitors measure 5-6 freon monitoring points in automatic mode, and 1 gas analyzer is installed at each point, low-temperature chamber, and this complicates the freon monitoring system. In our case, we suck in air under each low-temperature chamber.

Especially relevant for European countries, where there are European Commission Directives on leaks and overconsumption of fluorocarbons, penalties for violators. In addition, the European Union has a whole Decarbonization program with a gradual reduction and cessation of the use of fluorocarbons by 2050.

Calculation

The economic effect consists of savings on freons, maintenance costs for a refrigeration service company, and a reduction in fines as a result of eliminating freon leaks in refrigeration equipment in supermarkets.

Top management and owners of the supermarket chains themselves. 1.1. The implementation of systems for monitoring and blocking freon leaks has a colossal benefit for them. For example, 100 supermarket chains with low-temperature volume complexes, chambers up to 1000 pieces in Europe can have freon leaks of up to 30%, and half of them with a complete freon leak of up to 2 kg of freon in the refrigeration volume.

100 networks with 10 stores, 10 volumes in each store = 10,000 volumes. Minimum 2 kg per volume = 20,000 kg. min 20,000 kg of refrigerant — this is if the leak is detected in time. And since in the metro with a centralized refrigeration system (i.e. where there is one compressor and pipes with the distribution of refrigerant by volumes go from it), then from 20 to 50 kg can go away due to one leak in one volume. So it turns out 100 networks with 10 stores = 20,000 — 50,000 kg.х 30 euro = 600 000 — 1 mln. Euro. In other words, economic losses from freon reach up to 1 million euros.

On average, maintenance and technical repairs per supermarket per year amount to 10,000 euros x 1,000 supermarkets can be reduced by 40% and this will amount to 4 million euros.

The typical U.S. grocery store spends about $101,900 every year on all equipment repairs and maintenance, says the report. One third of that budget—a whopping $33,900—goes to the refrigeration trades. (HVAC and general repairs tied for second place with each eating only 9% of the total spend).

It makes sense. Today’s groceries have more refrigeration equipment than ever before and maintaining that cold chain is critical for food safety and customer trust. But the bulk of these service calls are for repairs, not maintenance. According to the report, the average store calls their refrigeration repair service 36 times a year. Even worse, half of those calls are emergencies, requiring a faster turn around and an even higher price tag.

In all, only 11% of the total repair and maintenance budget goes to actual preventive maintenance. Yet proper maintenance is the best way to avoid disruptive operational failures and expensive repairs. Running dirty cooler cases costs money in four ways.

- Increased power bills: Commercial refrigerators and freezers with dirty or clogged evaporator coils require almost double the electricity to work as well as appliances with clean coils.

- Shortened cooler life: Dirty, clogged coils force machinery to work harder to maintain temperature. Over time, this causes motors to overheat, burn out, or malfunction altogether.

- Increased service calls: One grocery chain estimates that half of all service calls are caused by dirty equipment. Cutting down on some of those calls promises to save money.

- Spoiled product and consumer mistrust: Cooler cases that leak, smell weird, or have an unappealing layer of sludge collecting at the base compromise food quality.

- Customers will notice and shop elsewhere.

Approximately the same in the European Union (100,000 euros x 1,000 supermarkets) x 9% = 9 million euros.

Half of which is spent on maintenance and current repairs due to freon leaks. Approximately 4.5 million euros.

REGULATION F-GASES BY EUROCOMISSION

https://www.aquilar.co.uk/f-gas-regulation/#

This press release has been updated on 19 October to include the texts of the provisional agreements.

The Council and Parliament negotiators today reached a provisional political agreement on phasing down substances that cause global warming and deplete the ozone layer.

This provisional agreement finalizes negotiations on fluorinated greenhouse gases (F-gases) and confirms an informal agreement reached in June on ozone-depleting substances (ODSs).

While existing EU legislation has already limited the use of F-gases significantly, the new rules would further reduce their emission into the atmosphere and contribute to limiting the global temperature increase, in line with the Paris Agreement.

Fluorinated gases

According to the provisional agreement, the consumption of hydrofluorocarbons (HFCs) will be completely phased out by 2050, and the production of HFCs, in terms of production rights allocated by the Commission, will be phased down to a minimum (15%) as of 2036. Both production and consumption will be phased down based on a tight schedule of decreasing quota allocation (Annexes V and VII). The agreement introduces a higher quota allocation for the first two periods compared to the Commission proposal. Semi-conductors will be exempted from the HFC quota allocation system, as proposed by the Commission, and the feasibility of the phase-out of the consumption of HFCs and the need for HFCs in sectors where they are still used will be reviewed in 2040, taking into account technological developments and the availability of alternatives to HFCs for the relevant applications.

The text introduces a full ban on placing several categories of products and equipment containing HFCs on the market, including certain domestic refrigerators, chillers, foams and aerosols (Annex IV). It brings forward some deadlines for the ban and extends it to products that use F-gases with a lesser global warming potential (GWP). Exemptions from the ban are provided for if there are safety concerns.

The provisional agreement introduces a full ban on small (<12kW) monobloc heat pumps and air conditioning that contain F-gases with a GWP of at least 150 starting in 2027, and a complete phase-out in 2032. With regard to split air conditioning and heat pumps containing F-gases, the co-legislators agreed on a full ban starting in 2035, with earlier deadlines for certain types of split systems with higher global warming potential. Exemptions are provided for in cases where this equipment is needed to meet safety requirements. The provisional agreement also includes the possibility to release a limited number of additional quotas for heat pumps if the proposed bans were to endanger the attainment of the heat pump deployment target required under RE Power EU.

The implementation of the project Blocking Freon Leaks has a stimulating value for the creation of a new type and approaches to reduce the use of F gases in refrigeration equipment. Supermarket chains where Blocking Freon Leaks will be used will create an image of a Safe Ecological Supermarket Chain. They will protect themselves from loss of reputation in the event of an accident and Freon leaks, environmental fines and criminal liability.

The text also lays down a new full ban on medium voltage switchgears relying on F-gases, with a gradual phase-out by 2030, and a ban on high voltage switchgears by 2032. It introduces a cascading principle that allows for potential derogations from the bans depending on the bidding process for F-gas-free alternatives. It includes a possibility for high voltage switchgear to use the very potent greenhouse gas SF6 as a last resort under the cascading principle and adds a number of safeguards in order to avoid the bans endangering the functioning of the electrical grids.

The provisional agreement introduces a ban on some equipment needed to repair and service existing equipment. From 2025, servicing equipment for refrigeration equipment that uses F-gases with high global warming potential will be banned unless the gases are reclaimed or recycled, in which case they benefit from a derogation until 2030. A similar ban is introduced for servicing equipment for air conditioning and heat pump equipment for 2026, with a derogation for reclaimed or recycled gases until 2032. A servicing ban on stationary refrigeration equipment designed to cool products to temperatures below -50 °C using F-gases with lower global warming potential will be applied in 2032, with a permanent derogation where recycled or reclaimed gases are used.

The text sets the HFC quota allocation price at €3, adjustable for inflation. Part of the revenue will be used to cover the administrative costs of the implementation of the F-gas regulation, and the rest will go to the general EU budget.

The text sets out a mandatory extended producer responsibility (EPR) scheme from 1 January 2028 for F-gases in products and equipment which fall under the categories of electrical and electronic equipment subject to Directive 2012/19/EU (on waste electrical and electronic equipment).

The provisional text provides that member states will set rules on effective, proportionate and dissuasive penalties applicable to infringements. The penalties should include at least fines, confiscation of products, temporary exclusion of products from public procurement and temporary trade bans. They should be compatible with the Environmental Crime Directive and with national legal systems. They should be above a set minimum quantitative threshold if member states decide to set a threshold.

The implementation of the project Blocking Freon Leaks has a stimulating value for the creation of a new type and approaches to reduce the use of F gases in refrigeration equipment. Supermarket chains where Blocking Freon Leaks will be used will create the image of a Safe Ecological Supermarket Chain. They will protect themselves from loss of reputation in the event of an accident and Freon leaks, environmental fines and criminal liability. The project is well scalable, innovative and pioneering with a market of up to 100,000 refrigerated complexes.

Guidance

This Guidance Note is published by the Environmental Protection Agency (EPA) and is aimed at assisting operators of equipment containing Fluorinated Greenhouse gases (F-gases) and/Ozone Depleting Substances (ODS) to comply with the relevant European Regulations in the Republic of Ireland.

This Guidance Note also introduces Regulation (EU) No. 517/2014 — hereinafter referred to as the F-gas Regulation) which came into force on 1 st January 2015 and repealed F-gas Regulation EC No. 842/2006 — hereinafter referred to as the ‘repealed F-gas Regulation’). The existing ten Commission (Implementing) Regulations, associated with the repealed F-gas Regulation are still currently applicable and are listed in Appendix 1. The ODS Regulation (Regulation (EC) No.1005/2009) remains unchanged and sets out obligations relating ODS and equipment containing ODS. The F-gas and ODS Regulations are European Regulations that are directly in force in all EU Member States. The purpose of these Regulations is to reduce the impact of F-gases on climate change and of ODS on the further depletion of the ozone layer, by reducing emissions of F-gases and ODS respectively through HFC Phase Downs and Service Bans. This Guidance Note is primarily aimed at operators of equipment containing ODS and F-gas. Key changes introduced in the F-gas Regulation include:(i) Extended containment provisions to include refrigerated units of trucks and trailers, switchgear with some derogations, organic Rankine cycles. (ii) Leak checking frequency based on the Global Warming Potential1 (GWP) of the F-gas (this was previously based on the charge (in kg) of an F-gas).(iii) Service and maintenance ban using high GWP refrigerants in 2020, but the use of recycled and reclaimed gases will be allowed until 2030.(iv) Some equipment which did not previously require leak checking may now need to be checked, and (v) Some equipment which did not previously require automatic leak detection equipment may now need such equipment to be installed.

In this Guidance Note changes to, and new requirements of, the F-gas Regulation are flaggedfor ease of reference using the word ‘New!’, where relevant. Guidance documents relating to the obligations of operators of electrical switchgear2(containing SF6), refrigerated trucks and trailers3 and Air Conditioning (AC) equipment in road vehicles is available at www.fgases.ie.

F-gases are very powerful greenhouse gases that contribute to climate change if emitted to the atmosphere. F-gases include hydrofluorocarbons (HFCs) which are commonly used as refrigerants and Sulphur hexafluoride (SF6) and Perfluorocarbons (PFCs). Most F-gases have a relatively high GWP, and thus contribute to global climate change if released to the atmosphere. The objective of the F-gas Regulation is to protect the environment and combat climate change by reducing and preventing emissions to atmosphere and encouraging the use of low GWP F-gases.